After weeks of developing and testing, EURA DRIVES has validated the first software version for all types of pumping, this software will be soon available in the inverters E2000, EP66 and EM30. Until this happens, the load of the new EURA pumping software will be carried in our SAT of EURA.

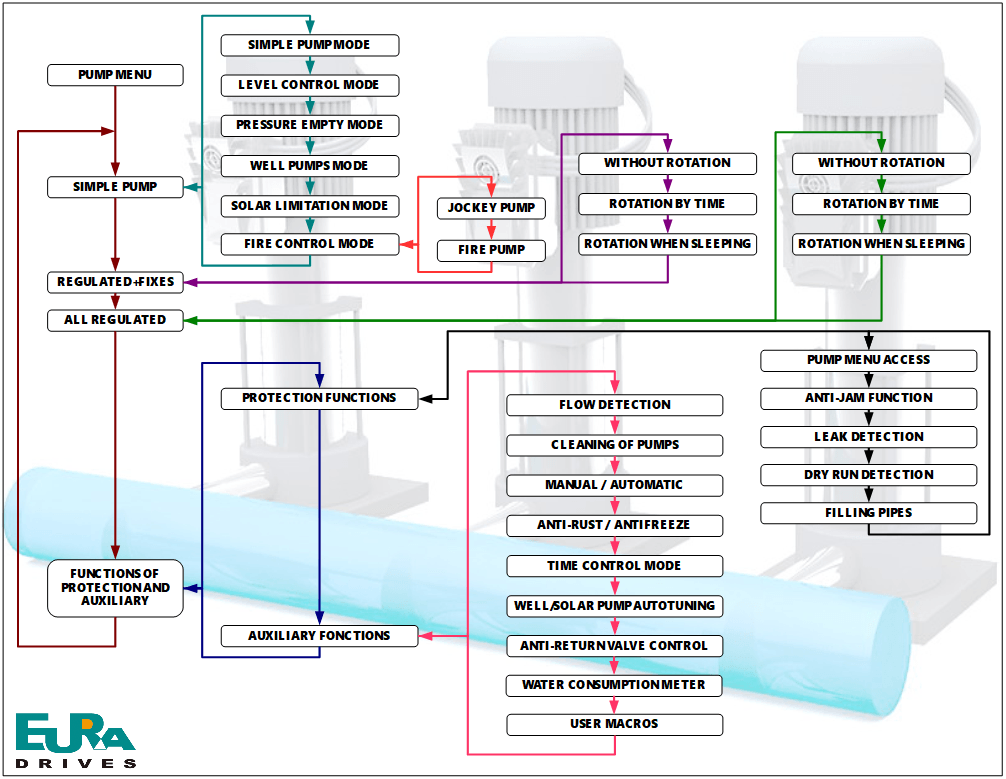

The selection of the pumping function desired is made by a “funnel” system, which filters the parameters required for each specific pumping mode.

With the new EURA DRIVES pumping software, the various pumping modes described below can be performed:

Menu structure of the new pumping software EURA DRIVES

Simple pump

1. Level control mode

It would be possible to do, with the same inverter, the pumping of a well or tank (to fill it or discharge it) conditioned by level. This mode can be combined with the well pumping or solar pumping modes.

2. Pressure discharge mode

With this pumping mode, it will be possible to discharge a tank or sump in pressure, but supervising the capacity of the supply. It also possible to alternate between the pressure sensors or the level sensor.

3. Well pumps mode

In this pumping mode, the pumping will be managed with a well pump, both for pressure irrigation and for tank filling. It can be combined with the level pumping mode. Important auxiliary function: Anti-return control valve.

4. Solar pumping with or without irradiation sensor

It is common that the solar pumping is combined with the well pumping mode, the pumping will be managed by a well pump powered by solar energy. The maximum use of the solar energy is carried by an exclusive control algorithm, which optimizes the solar resourses to the maximum all the time. This mode can be combined with the level pumping mode and pressure irrigation.

5. Fire mode

This pumping mode could be selected if the invertes are used to managed the Jockey pump(s) and the fire-fight pump(s).

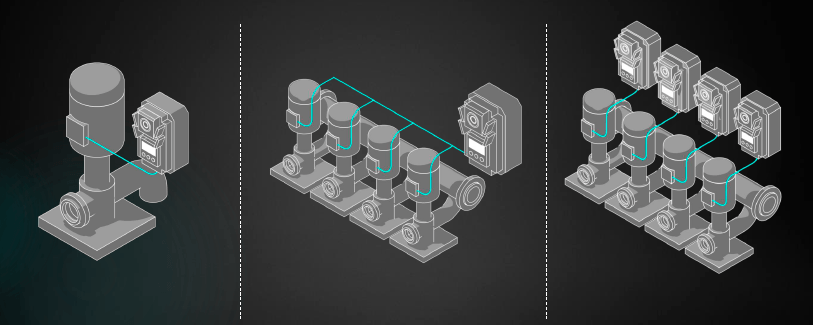

One regulated pump + up to three fixed pumps

EURA DRIVES has wanted to mantain this method of operation despite the fact that, nowadays, the “All Regulated” method is the most used due to the enormous improvement in regulation and the fact that with the advantageous prices of EURA DRIVES there is very little economic saving in realtion with the enormous difference of regulation between this two modes.

1.- Without rotation

With this mode, the fixed pumps to support the regulated pump always start its operation in the same order.

2.- Rotation by time of use

In this mode, the order of the start running of the fixed pumps to support the regulated pump changes after the adjusted working time of the regulated pump.

3.- Rotation after falling sleep the regulated pump

However, with this pumping mode, the order of the start running of the fixed pumps to support the regulated pump changes after the regulated pump goes to sleep because no pressure is required.

All regulated pumps

This is the most used pumping method in pressure groups (also called overpressure groups). It is possible to chain up to 15 pumps, all controlled by an inverter, and keep a certain pressure in the outlet manifold. It can also be used to keep a constant vacuum in a facility, or keep a constant flow in a pipe, or a certain temperature in a sump, or a constant level in a tank or sump.

You can configure the following three modes:

1.- Without rotation

With this mode the regulated pumps always start running and fall asleep in the same order.

2.- Rotation by time of use

In this mode, the order in which the regulated pump start running and fall asleep changes after the adjusted working time of the pump doing the Master function.

3.- Rotation after falling sleep the regulated pump

However, with this pumping mode, the order in which the regulated pump start running and fall asleep changes after of the pump doing the Master function falls asleep because no pressure is required.

Important auxiliary functions: Water flow detection, Leak detection, Dry running detection.

Protection functions

1.- Access protection

The parameterization can be protected so that it is not altered by the user (except for the setting of the setpoint.

2.- Anti-jam protection

The monitoring of the pump can be activated to detect a blockage produced by a solid body in the body of the pump, and try to solve the problem.

3.- Leak detection

Leak detection is an important protection, which can be activated if it is thought to be necessary. It detects the rupture of the outlet pipe and allows to give an alarm in the case of non-recovery.

4.- Dry running detection

This function is also very important and demanded by installers. It allows the detection of the condition of lack of water and activate the alarm, protecting the installation.

5.- Filling of the installation

If necessary, you can fill the installation in an automated way, and if you do not achieve it in the programmed time an alarm is activated, thus protecting the installation.

Auxiliary functions

The auxiliary functions have been developed to be combined with the various pumping modes described above. They are summarized in the following list:

1.- Water flow detection

It allows to supervise that the pump is not uselessly turbine the water in its internal chamber, and can reach the threshold to fall asleep.

2.- Cleaning of the pump

This function allows the cleaning of the pump impellers when it is estimated that they may have solid bodies.

3.- MANUAL/AUTOMATIC control

With this function you can have a pressure when the pump is set MANUAL and a different one when it is in AUTOMATIC mode. The variables to fall asleep will also be different. The mode is activated by external digital inputs.

4.- Anti-rust/Anti-freeze

This function allows the pump to be started at a certain speed and for a certain time in case of prolonged shutdown.

5.- Timer

It is available (see for which series) a temporary programmer, to do irrigation at variable pressure according to the time of day, the day of the week, and the month of the year.

6.- Solar/well pump autotuning

This function allows to automatically detect the threshold of the pump so that it falls asleep effectively.

7.- Anti-return valve control

This function allows to protect the pump in the event of not having an anti-return valve.

8.- Flow meter

If it is necessary to control the consumption of the fluid used, this function performs this task. The counting impulses must come from the correct measuring instrument installed, and through a digital input in the inverter.

9.- User macros

The parameterization of the pump can be saved in the keypad memory. You can saved two different configurations, and download them in this or another inverter.

In the downloads section of this webside, you can download the pump manual.